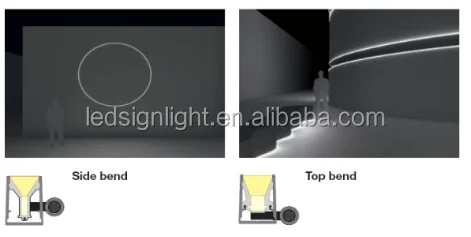

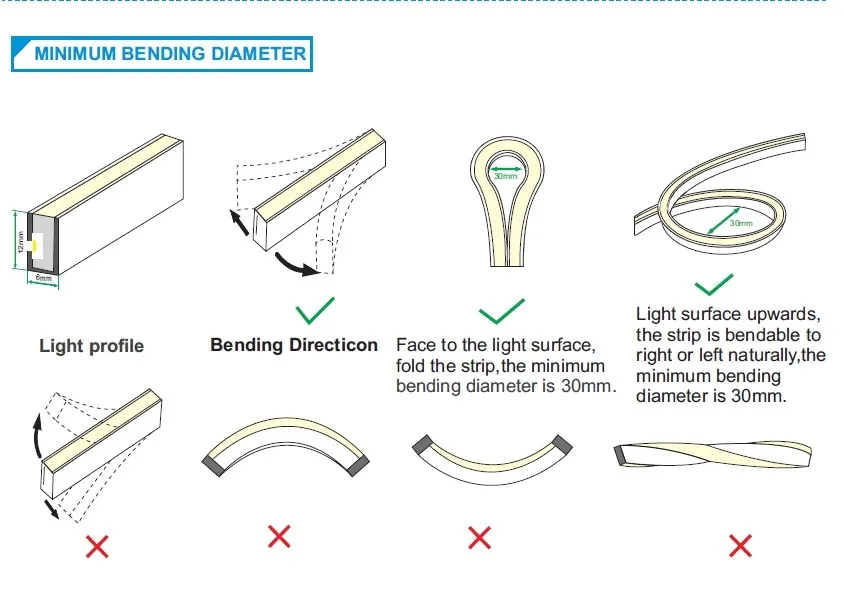

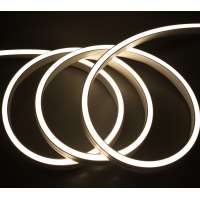

*Flexible horizontal bending strip,ultra slim only 6mm

*Dual-color silicone extrusion

*Enhanced SMD2835 LEDs especially for neon products, DC24V

*120 LEDs per meter, can be cut every 6 LEDs(50mm)

*UV resistant and salt mist proof

*Minimum bending diameter 30mm

*CE,RoHS,UL certificate